Development of a Silicon Retinal Implant: Microelectronic

System for Wireless Transmission of Signal and Power

I. Abstract

Purpose. To develop a method of wireless communication to

supply power and signal (visual scene detail) to an epiretinal

prosthesis.

Methods. In this system, now partly built and electronically

tested, an external laser provides signal and power to the implant.

An 820nm laser beam enters the eye, illuminates an internal

photodiode array, powering the microchip upon which the array is

mounted. Chip circuitry interprets small, rapid intensity

variations, deliberately modulated on the laser beam to encode scene

detail, and uses them to determine the location, duration and

intensity of electrical stimulation passed to retina through a dense,

implanted microelectrode array.

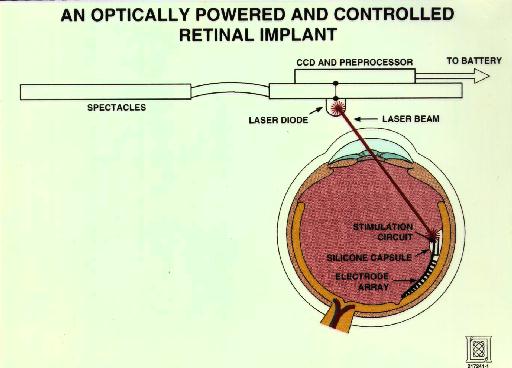

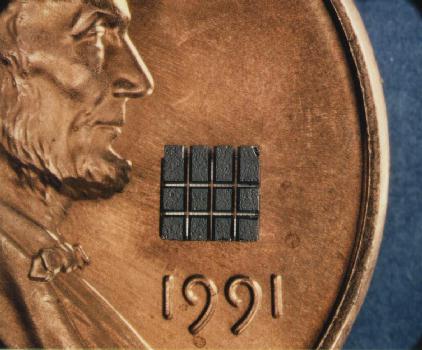

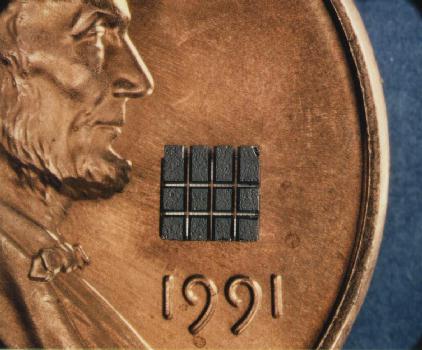

Results. A 12-cell phototdiode array, 2.2 mm square, was

fabricated. Its power efficiency of 18% is adequate to power the

chip with a 1W/sqcm beam, weak enough to avoid retinal damage at this

wavelenth. The array was then attached to a glass covership and

electrically isolated via a saw-etch technique. The chip, which was

fabricated in a 214 CMOS process, consists of about 10,000 transitors

and occupies a 2.2mm X 2.2mm area. The voltage and currrent

regulators, high frequency filters, logical cuircuits, and electrode

drivers function as expected, but the reference circuits need

additional buffering and a slightly modified design is under

fabrication.

Conclusions. Test results indicate that needed functionality

can be achieved within power and area budgets. The modified circuit

for the epiretinal prosthesis should be available for experimental

implantation in 1994.

II. Introduction

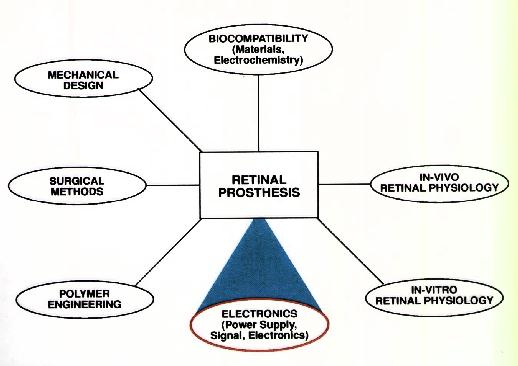

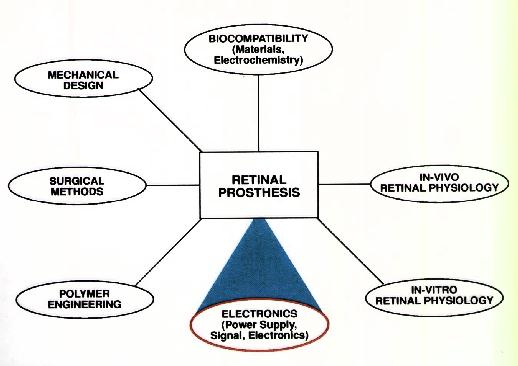

This research is part of the Retinal Implant Project, a collaborative

effort of the Massachusetts Eye and Ear Infirmary and the

Massachusetts Institute of Technology. The goal is to develop an

independently functioning, epiretinal prosthesis to restore vision to

patients with disease of the outer retina, especially retinitis

pigmentosa and macular degeneration. This poster represents work

within one of the seven areas of the overall research effort.

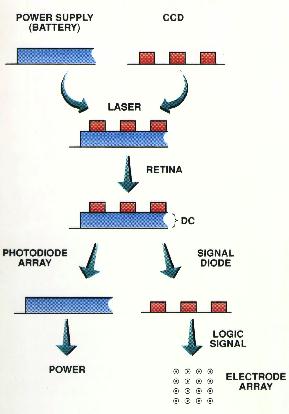

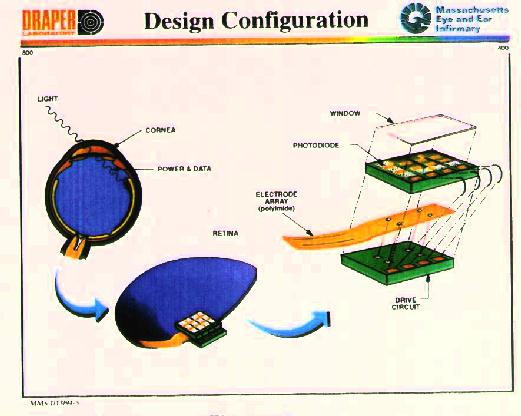

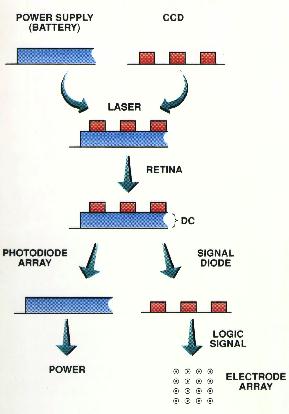

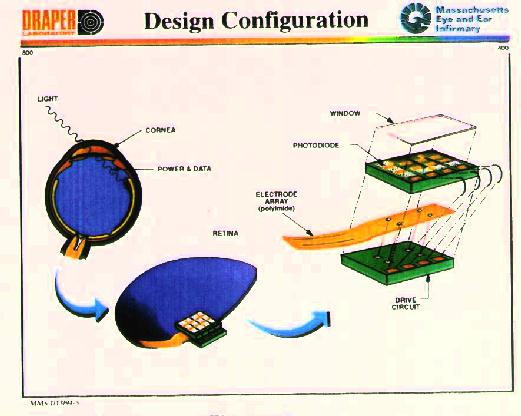

Figure 1

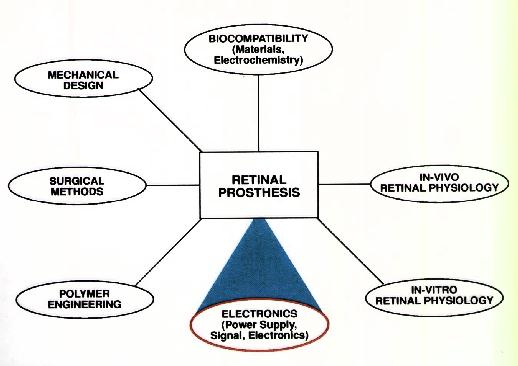

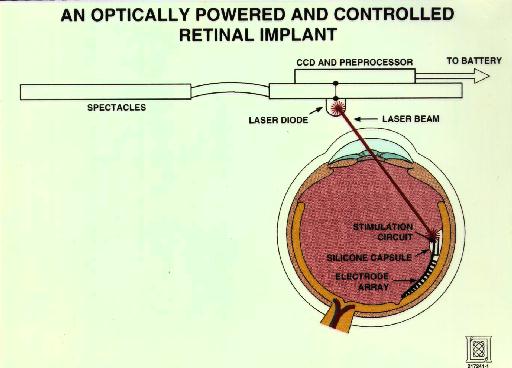

Design goals include placing as few components as possible within the

eye and providing power and signal to the implant without having to

penetrate the eye with wires (Figure 2). The design achieves these

ends by:

- Capturing the visual scene with a tiny CCD camera mounted

on eyeglasses,

- Encoding the image in small variations in the beam

intensity of an externally mounted laser,

- Tranmitting the processed beam to the microchips implanted

within the eye, adjacent to the retina.

Combining Power and Signal Components for Optical

Transmission to Retinal Implant Circuit

The small, external laser (820 nm) is powered by a battery and its

output modulated by a pulse stream from the CCD sensor, which

represents the visual scene. The modulated laser output is incident

on the intraocular photodiode array (Figures 3-4), which generates

the electrical supply voltage. This electrical supply powers the

stimulator circuitry (see next panel, central). Variations in the

incident laser beam are first read by the signal photodiode, then

transferred to and decoded by the stimulator chip and finally used to

control the location and timing of electrical pulses. The pulses are

sent to the flexible electrode array which sits in curved position

against the retina.

Figure 2

An Optically Powered and Controlled Retinal Implant

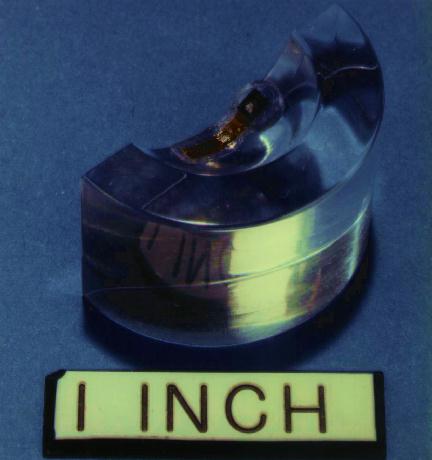

Figure 3

Top surface of twelve-cell photodiode

array, which powers the stimulator chip.

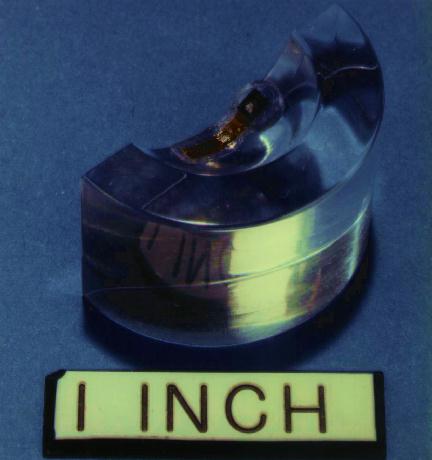

Figure 4

Back surface of the photodiode array. This view demonstrates the

sawed incisions that are used to prevent current leakage between

cells.

Transmission of Power and Signal on a Single Laser Beam

As indicated in Figure 5, the overall beam intensity (blue) is

sufficient to drive the implanted photodiode array and power the

stimulator chip. Details of the visual scene are encoded in the

pulse stream by superimposition of an amplitude modulated signal

(orange) upon the DC laser output. The modulated signal is detected

by an internal signal photodiode that converts the optical signal

into the electrical input to the stimulator logic. The logic

controls current sources that excite the electrodes, which produce a

pattern of biphasic pulses intended to stimulate the retinal ganglion

cells with a spatial pattern representative of the initially viewed

30 image incident on the CCD sensor.

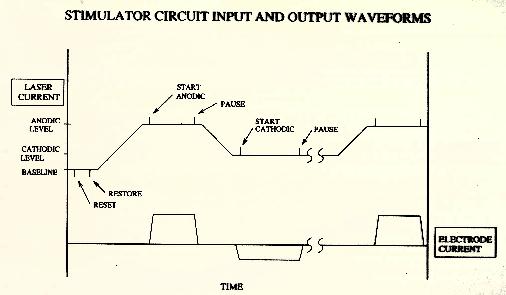

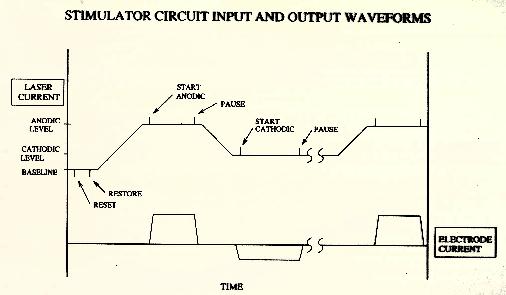

Figure 5

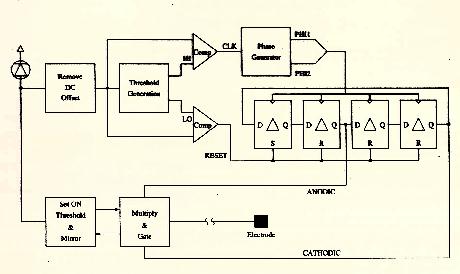

For Preliminary Experiments, This Curcuit Stimulates

all Electrode Simultaneously

The laser light waveform allows independent control of the output by

carrying the following information (see Figures 6-8):

- amplitude of the anodic pulse -- given by sampling the input

level during the anodic stimulation period.

- amplitude of the cathodic pulse.

- beginning and end times of the anodic pulse -- determined by the

time between the first two positive pulses.

- beginning and end times of the cathodic pulse -- determined by

the second pair of positive pulses.

- the reset that begins a new cycle -- initiated by the first

negative pulse.

- elimination of accumulated electrode charge by shorting the output to a

reference voltage -- initiated by the second negative pulse.

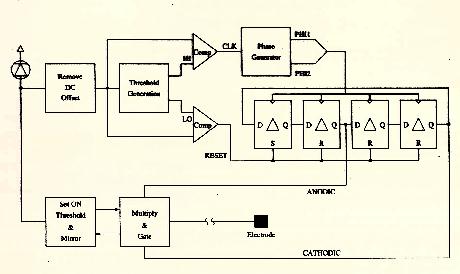

Figure 6

Figure 7

Figure 8

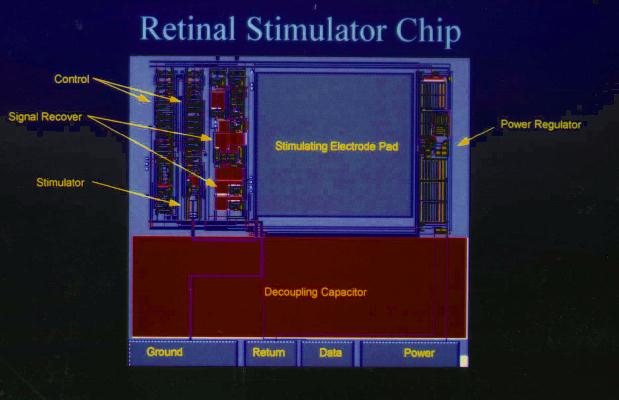

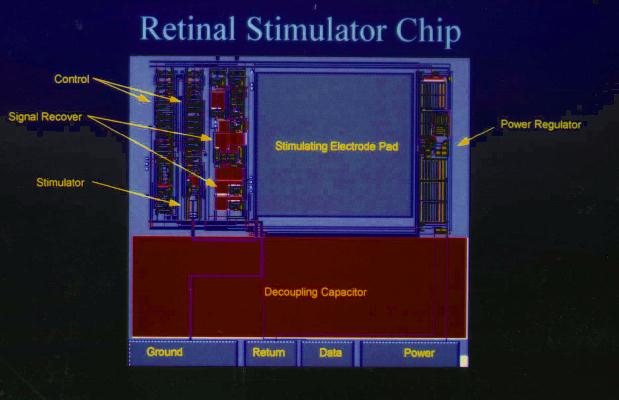

Stimulator Chip

The stimulator chip (Figure 9) recognizes variations in the signal

diode output that represent beam intensity fluctuations due to the

encoded visual signal. These variations drive a small finite state

machine that in-turn drives the electrodes cathodically or

anodically, or alternatively crreates open circuits or shorts between

the electrodes. Beam intensity governs the strength of cathodic and

anodic stimulation.

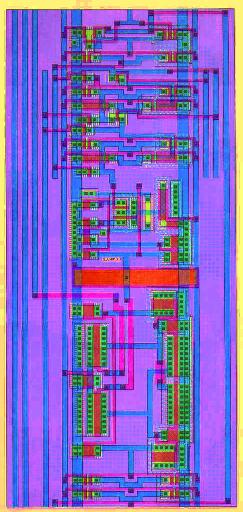

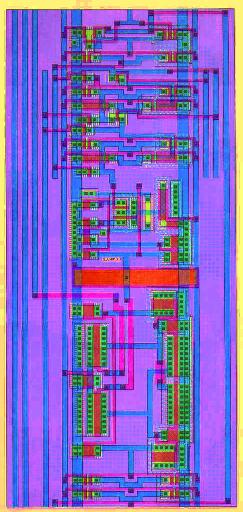

Expanded view of delay circuit (Figure 8), representing a region

about 1/2 inch in length in the layout of the stimulator chip (Figure

7). Each transistor (red strip surrounded by green on both sides) is

laid out by hand. The thin red polysilicon lines are 2 microns in

width.

Figure 9 Block Schematic of Stimulator Circuit

The implant consists of a thin, flexible polimide electrode array

sandwiched between two silicon microchips (Figure 10). The upper

chip contains the photodiode array and signal diode, which supply

electrical power and visual signal information to the underlying

stimulator chip (i.e., drive circuit).

Cantilevered polyimide electrode array (Figure 1 1). The

prototype implant contains only twenty electrodes (shown at the top)

and these electrodes are wired in parallel to provide simultaneous

stimulation. The seven possible contact points allow a variety of

choices for total lenght of the array.

Enlarged view of several electrodes (Figure 12). Each is 25

microns in diameter and has been plated with platinum black, which

reduces electrical resistance and increases surface area (which

reduces the local concentration of toxic electrochemical byproducts).

Monolithic Silicon Stimulator

The present retinal stimulator apparatus is a hybrid structure using

thin metallized polyimide for the electrode array, which is

wire-bonded to a silicon integrated circuit that is connected in turn

to the optically powered supply source. For implants comprising

thousands of stimulating electrodes, a fully monolithic structure

built from thinned silicon is the best solution to forming the large

number of electrodes that must be connected to the stimulating

electronic circuit.

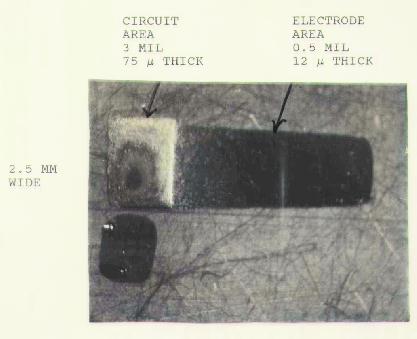

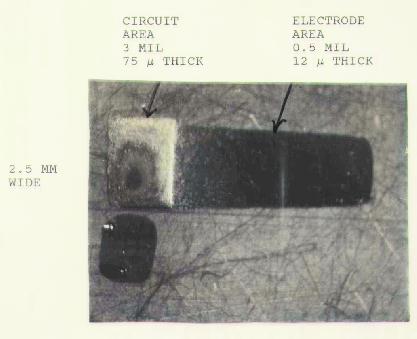

Figure 13 shows a mechanical model of thinned silicon in which

the cantilevered area that would contain the electrode array is only

12 microns thick, and the circuit area is 75 microns thick. The

black rectangle below was used to mask the circuit area during final

thinning of the array.

Figure 10 Design Configuration

Figure 11

Figure 12

Figure 13

Figure 14

III. Discussion

The design of the electronic system provides three significant

benefits:

1. Minimizes the amount of electronics that need to be placed in

the eye

The risk of electronic failure is partially related to how much

electronics is placed into the eye. The eye is basically a hostile

environment for electronics -- even minute quantities of salt will

destroy the chips, Also, faulty internal components could only be

changed by undertaking additional surgery. Therefore, it is

desirable to internalize only those components that absolutely need

to be intraocular.

2. Permits changes to be made in the signal drive without having

to perform additonal surgery

It can be safely assumed that whatever stimulation strategies are

chosen, perception will not likely match our expectations. The

ability to alter the function of the internal chip without entering

the eye is a great advantage. New developments in image coding can

be used to upgrade the system. Patients can provide feedback that

could be used to individualize the stimulation protocol.

3. Eliminates the need for wires

Both signal and power are provided by the invisible laser light.

Radiofrequency could also be used to provide both signal and power,

but light offers the advantage that much greater volume of data can

be transmitted. Infrared light is also advantageous in that the 820

nm wavelength is just above the bandgap of silicon, which means

optimum efficiency for energy transfer. This higher efficiency

reduces the intensity of light needed to power the chip, which

lessens the risk of light-induced retinal damage.

The electronic design also includes low-power circuitry, which

was specially designed for this project. The lowered energy demand

lessens the amount of energy that needs to be transmitted into the

eye, and proportionately increases the amount of current that can be

delivered to the electrodes. This luxury potentially increases the

number of electrodes that can be driven by a given amount of energy

entering the eye.

The chip also has a fairly unique property. When there is a

"power failure", as will occur with each blink of the eyelid, the

chip shuts down in a known state. When power is restored, the chip

begins to function in that known state (without having to "reboot"),

which improves its efficiency.

IV. CONCLUSION

- The most serious challenge facing this project is the

uncertainty of biocompatibility at the neural-electrode interface.

- Both signal and power can be transmitted to internal components

without wires.

- Sufficient power can be transmitted with a relatively low

intensity of infrared light to drive 20 electrodes, which should be

more than adequate to produce a retinal response that we can detect

by recording from subdural electrodes positioned over the visual

cortex (see our adjacent poster # 592-40).

- All electronic components have been designed, manufactured and

tested. Invivo testing of the retinal prosthesis will begin shortly.