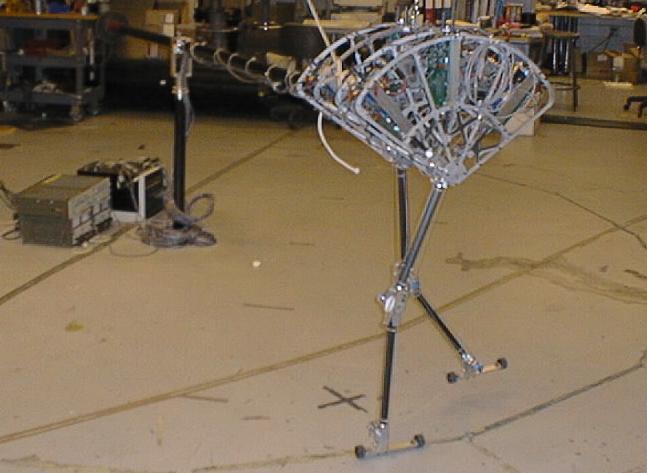

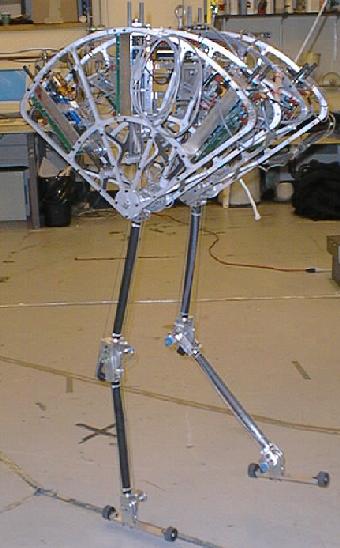

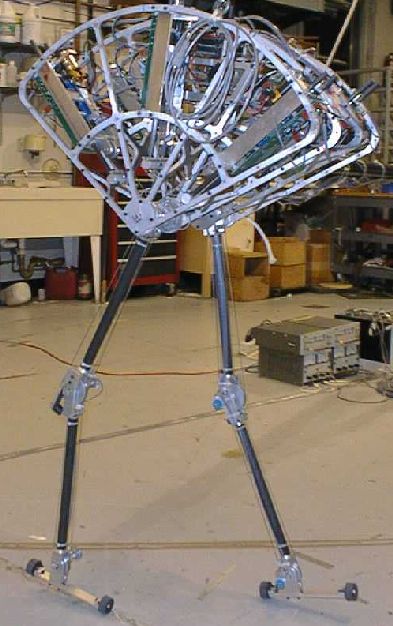

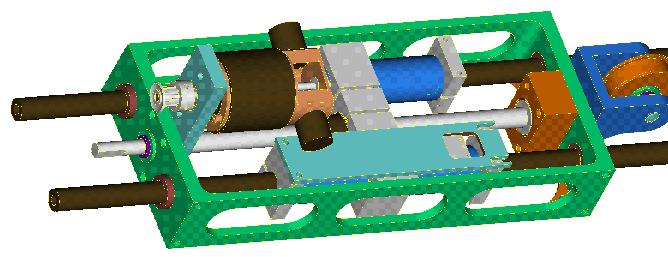

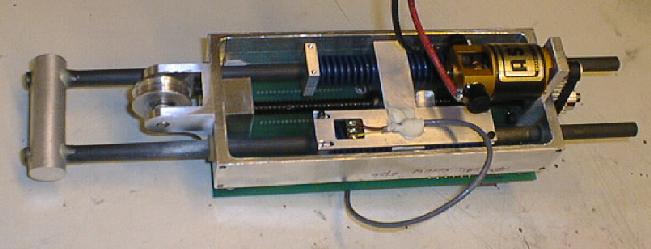

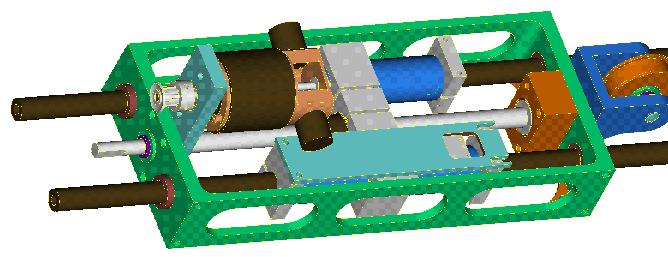

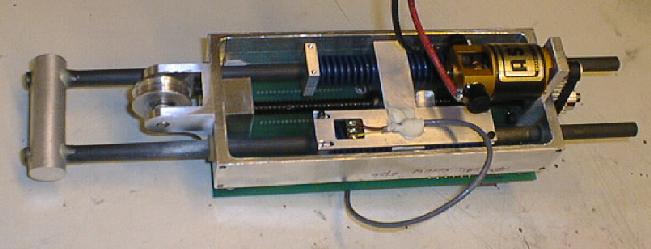

Series Elastic Actuator Design (top) and real thing (bottom). A brushed DC model airplane motor (Astroflight) drives a 2 to 1 timing belt reduction (Stock Drive - not shown in the design drawing). The timing belt is connected to a ball screw (Motion Systems) which moves the spring pusher which is between the compression springs (Century Spring). The spring pusher pushes on the springs which then push on the clamps which finally push on the output. A linear potentiometer (Novotechnic) measures the spring compression and thus the output force. Circuit board attached to the actuator is a simple PD controller which servos force (i.e. spring compression). Output is desired current which is fed to a current amplifier (Copley Controls). The robot has six identical copies of the actuator located in its body. The actuator attaches to a cable which then goes on to drive the appropriate joint. Attached to the actuator is the idle pulley for the cable.