As discussed in the section on our methodology, we believe that Cog's body can help Cog to behave like an intelligent creature. Several distinctive qualities are important to Cog's body and motor control. First, Cog has a body that is similar in shape, structure and degrees of freedom to a human body. Second, the actuators that move Cog's body use series elastic actuators which, among other benefits, ease the control of the body and make human interactions with Cog safer.

In total, Cog has twenty-two mechanical degrees-of-freedom (DOF): two 6-DOF arms, a 3-DOF torso, a 4-DOF neck, and 3-DOF combined in its eyes.

Design Criteria

Two fundamental goals guide the design of the body for Cog. First, the robot should be anthropomorphic to encourage humans to interact with it in a natural way. The most important human characteristics to emulate are size, speed, and range of motion. To achieve natural human interactions, we felt it would be better to build a robot with modest load-carrying capacity but human-scale speed. Second, the robot's hardware should use well-known technology and components to minimize design and construction time.

Range of Motion

Cog's torso has three degrees of freedom: the waist bends side-to-side and front-to-back, and the "spine" can twist. The neck adds four more degrees of freedom, but technically the neck is part of <a href="#head">the head</a>. Mechanical stops on the body give a human-like range of motion, as shown below. (The body twist (120 degrees) is not shown.)

Cog resembles a human from the waist up. The robot is mounted on a pedestal to simplify design and construction. The power supplies and most of the electronics are off-board, making it easier to provide ample power to the electronics and motors, yet fit the robot in a human-sized torso.

Power and Speed

Table 1 (shown below) summarizes the actuator requirements for the three degrees of freedom. The torque requirements were based on targets of a 5 lb head, 10 lb arms, and a 30 lb torso. The torso's mechanical components weigh in at 24 lb.; electronics and wires consume the rest of the weight allowance. The actuators in the torso are all DC gearmotors equipped with optical encoders for position sensing.

| Degree of Freedom |

Max Torque

(ft-lb) |

Max Speed

(rpm) |

Power

(W) |

| Waist Roll (side to side) |

100

|

3

|

50

|

| Waist Pitch (front to back) |

100

|

5

|

80

|

| Spine Twist |

20

|

15

|

50

|

Torso Sensors

Each degree of freedom has optical encoders to measure joint position. We are in the midst of fitting the torso motors with load cells as well, to yield a direct and precise torque measurement for torque control. There are also currently plans to implement a "skin" of tactile sensors for Cog.

Each of the two arms is loosely based on the dimensions of a human arm with 6 degrees-of-freedom, each powered by a DC electric motor through a series spring (a series elastic actuator, see (Pratt & Williamson 1995)). The spring provides accurate torque feedback at each joint, and protects the motor gearbox from shock loads. A low gain position control loop is implemented so that each joint acts as if it were a virtual spring with variable stiffness, damping and equilibrium position. These spring parameters can be changed, both to move the arm and to alter its dynamic behavior. Motion of the arm is achieved by changing the equilibrium positions of the joints, not by commanding the joint angles directly.

There is considerable biological evidence for this spring-like property of arms (Zajac 1989, Cannon & Zahalak 1982, MacKay, Crammond, Kwan & Murphy1986). The spring-like property gives the arm a sensible "natural" behavior: if it is disturbed, or hits an obstacle, the arm simply deflects out of the way. The disturbance is absorbed by the compliant characteristics of the system, and needs no explicit sensing or computation. The system also has a low frequency characteristic (large masses and soft springs) which allows for smooth arm motion at a slower command rate. This allows more time for computation, and makes possible the use of control systems with substantial delay (a condition akin to biological systems). The spring-like behavior also guarantees a stable system if the joint set-points are fed-forward to the arm.

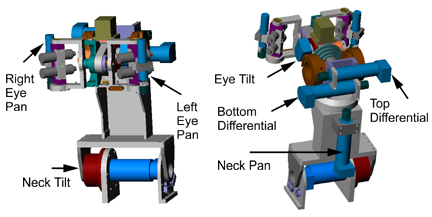

Cog's head was designed to mimic the range and speed of motion of the human head. There are seven degrees of freedom in the head, with three in the eyes and four in the neck. Two directly driven neck axes allow the robot to turn its head from side to side (neck pan/yaw), to lean forward from the base of the neck near the shoulders (neck tilt); a two-axis differential allows the robot to both nod its head up and down (head tilt) and to cock its head from shoulder to shoulder (head roll). The eyes have three degrees of freedom; each eye has an independent pan/yaw axis (which allows the robot to look right and left and accommodates vergence movements) and the two eyes share a single tilt axis (which allows the robot to look up and down). Each of the mechanical degrees of freedom in the head is equipped with a high-resolution optical encoder for determining position.

Cog's head also contains a variety of sensors for perceiving the world. To mimic the human retina, each eye has two cameras. In each eye, one camera provides a wide 120 degree field-of-view for peripheral vision and the other camera provides a narrow 20 degree field-of-view at high resolution for foveal vision. The head also contains a 3-axis inertial sensor which acts much like the human inner-ear. We use this inertial sensor for gaze stabilization (the vestibulo-occular reflex) and plan on using it in the future to provide a sense of balance.

We are still in the process of designing and fabricating the exterior shell for Cog's head, but you might want to look at Lazlo - Humanoid Face Project for the current status. Once the exterior shell has been integrated, we will install microphones to be used as ears.

Details of the Actuators

Each actuator of the arm consists of a DC electric motor with a series spring (so called Series Elastic Actuator). The spring allows low-noise force control from the geared electric motor.

Essentially, electric motors operate well at high speeds and low torques, but the majority of applications (including this one) require low speeds and high torques. This is usually accomplished by using a transmission, the most common type being a planetary gearbox. These types of gearboxes introduce friction, noise and backlash to the motor output, making it hard to achieve low-noise force control. To overcome this problem you can use a low friction, zero-backlash transmission such as a cable drive (which tends to be bulky and mechanically complex) or use direct-drive motors (which tend to be very heavy). The approach used here is to insert a spring between the motor drive and the load as shown in the figure below.

The spring is linear, so the output force is proportional to its twist. If the twist is measured, then a control law can force the actuator to maintain that twist, and so give a constant force output.

- The spring converts the force control problem into a position control one, which is better suited to the abilities of the motor-gearbox combination.

- The spring naturally low-pass filters the noise and backlash of the gearbox, giving a low-noise force output.

- Shock loads are absorbed by the spring protecting the motor gear teeth.

- Overall system bandwidth is low due to the spring.

- It is easy to make the actuator behave in a passive manner, making it stable while interacting with all environments. This means that an arm powered by this actuator will not go unstable when touching a hard surface.

You can see a short MPEG video (403Kb) of Cog's arm hammering a nail into a 2x4 piece of wood. ![]()

Similar actuator technology is used in a walking robot, Spring Turkey in the MIT Leg Lab.

Spring-Like Behavior

Human muscles have a spring-like property, which can be approximately modelled as in the figure below.

The joint has a springy behavior given by the two springs in the picture. The equilibrium point can be changed by moving A and B in opposite directions. For Cog's arms, each joint is programmed to behave in this manner, as a virtual spring with variable stiffness, damping and equilibrium point. This gives the overall arm some desirable properties.

- It is robust to collisions - the arm consists of masses connected by these virtual springs. If any part of the arm is deflected, the loads are taken up by the springs. There is no need for any explicit computation or compensation for collisions.

- Since the actuators can deal with shock loading there is no danger of damage from collisions either

- The system is stable: it consists of masses and springs which are all passive devices, so no stability problems.

- The system has a low frequency characteristic, meaning that commands to the arm at a low rate can still obtain smooth arm motion. This gives more time for computation.

[Methodology], [Overview], [People], [Video], [Publications]